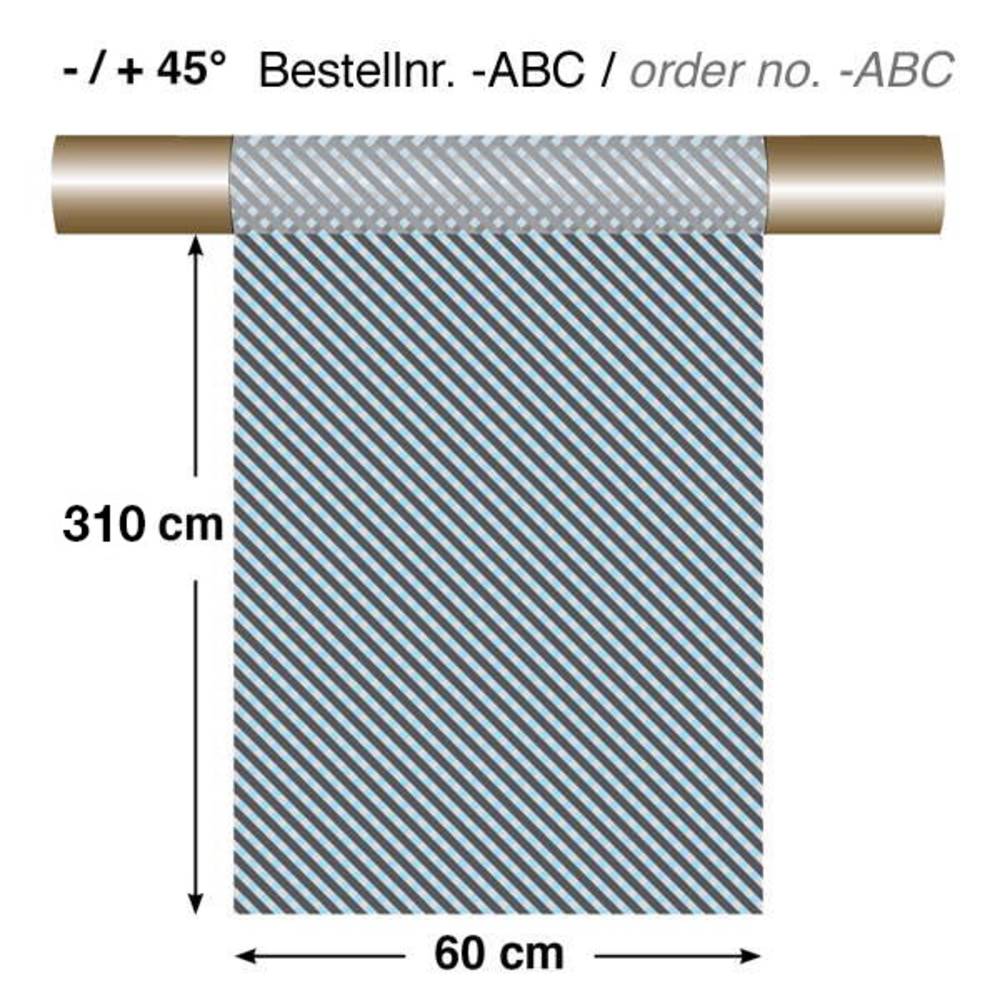

CARBOWEAVE® IMS Carbon NCF 30 g/m² (biaxial), 60 x 310 cm

Fibre: Tenax® IMS65 24k / 830 tex

IM carbon fibres (Intermediate modulus) are specifically suited for lightweight applications. In comparison with standard carbon fibres, for example, Tenax® HTS40 or Torayca® T300, this fibre provides approx. 20 % increased tensile modulus and approx. 25 % increased tensile strength at an almost identical elongation at break.

Width: 60 cm

Length: 310 cm

Surface weight (g/m²): 15 / 15

Construction: +/- 45° or -/+ 45°

When manufacturing very thin parts, such as trailing edges of wings and tails of model aeroplanes, it could be possible that these are becoming warped if no mirrored lay-ups are used. For this reason, we offer the Tenax® IMS65 types in +/- 45° as well as in -/+ 45° fibre orientation.

Application:

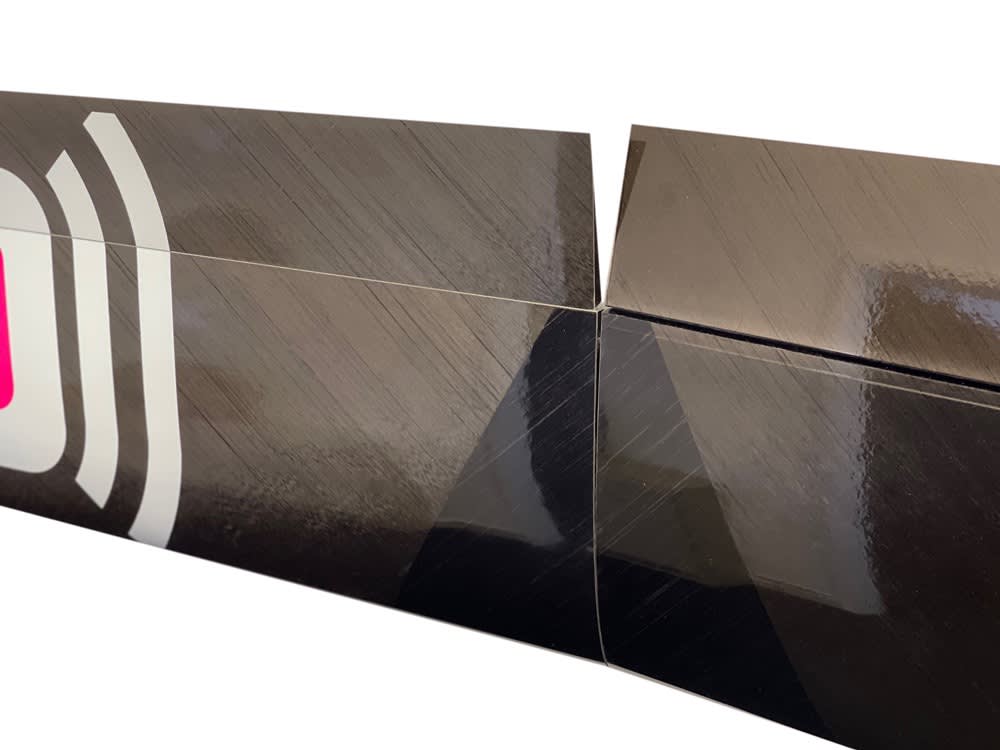

Motorsports, marine construction, sports equipment and model construction. This biaxial NCF has 2 unidirectional plies laid at an angle of ± 45° which are bonded with an epoxy-compatible binder to each other. Drapability is improved compared to conventional NCF with plastic scrim. Due to a very low thread deflection, the properties of the fibres are better exploited. Particular advantage: torsional layers could be done without an offcut.

Calculated data for hand laminates with 35 volume per cent fibres:

Resin consumption: 36 g/m², laminate thickness: 0.045 mm, laminate weight: 66 g/m²

Versions with Tenax® IMS65 for very robust, with Tenax® UMS40 for very stiff and with Tenax® HTS40 for robust parts are available.

Comparison of Tenax® Fibres

| |

IMS65 |

UMS40 |

HTS40 |

| Tensile strength, MPa |

6000 |

4700 |

4400 |

| Tensile modulus, GPa |

290 |

390 |

240 |

| Elongation at break, % |

1.9 |

1.2 |

1.8 |

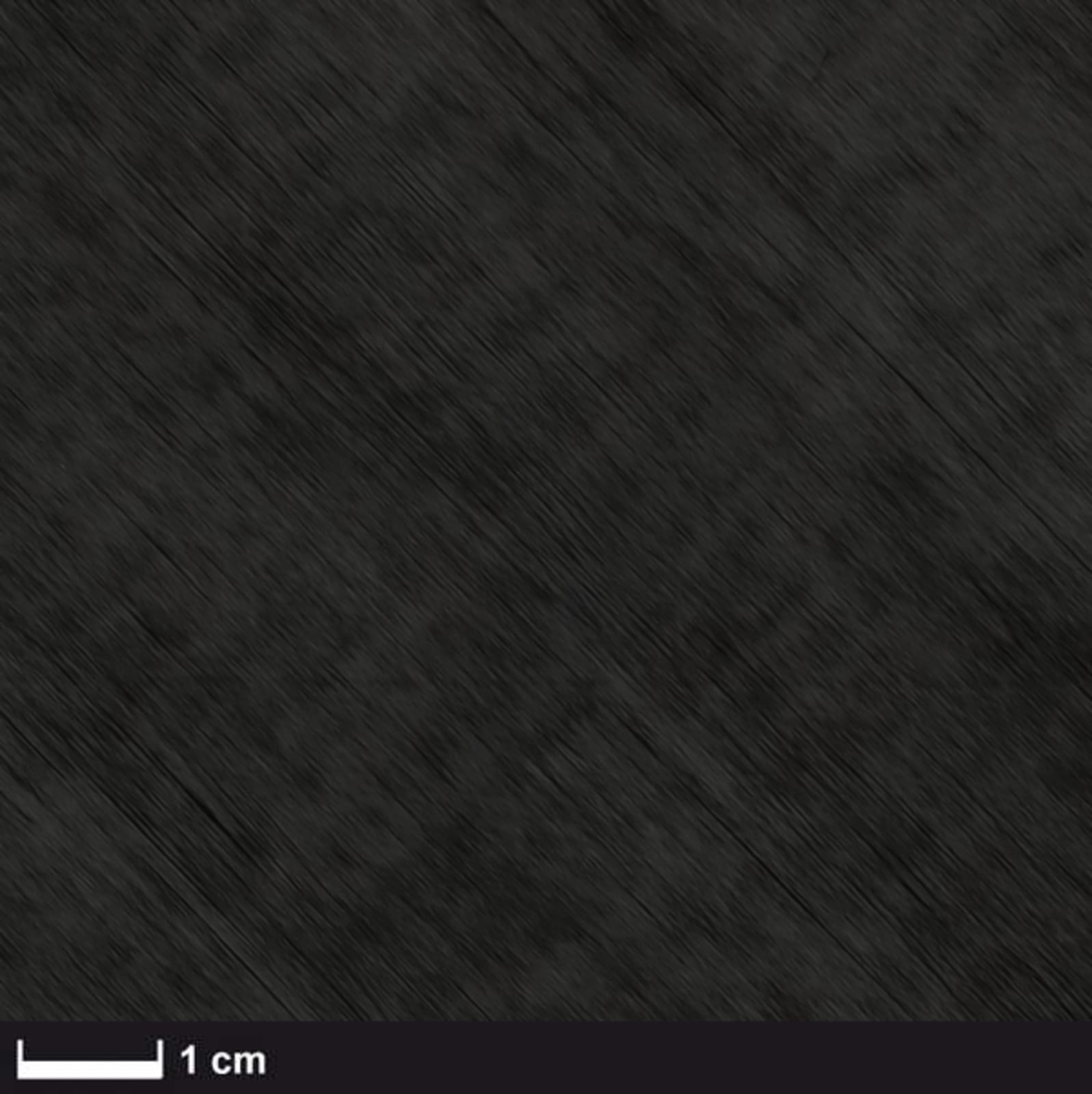

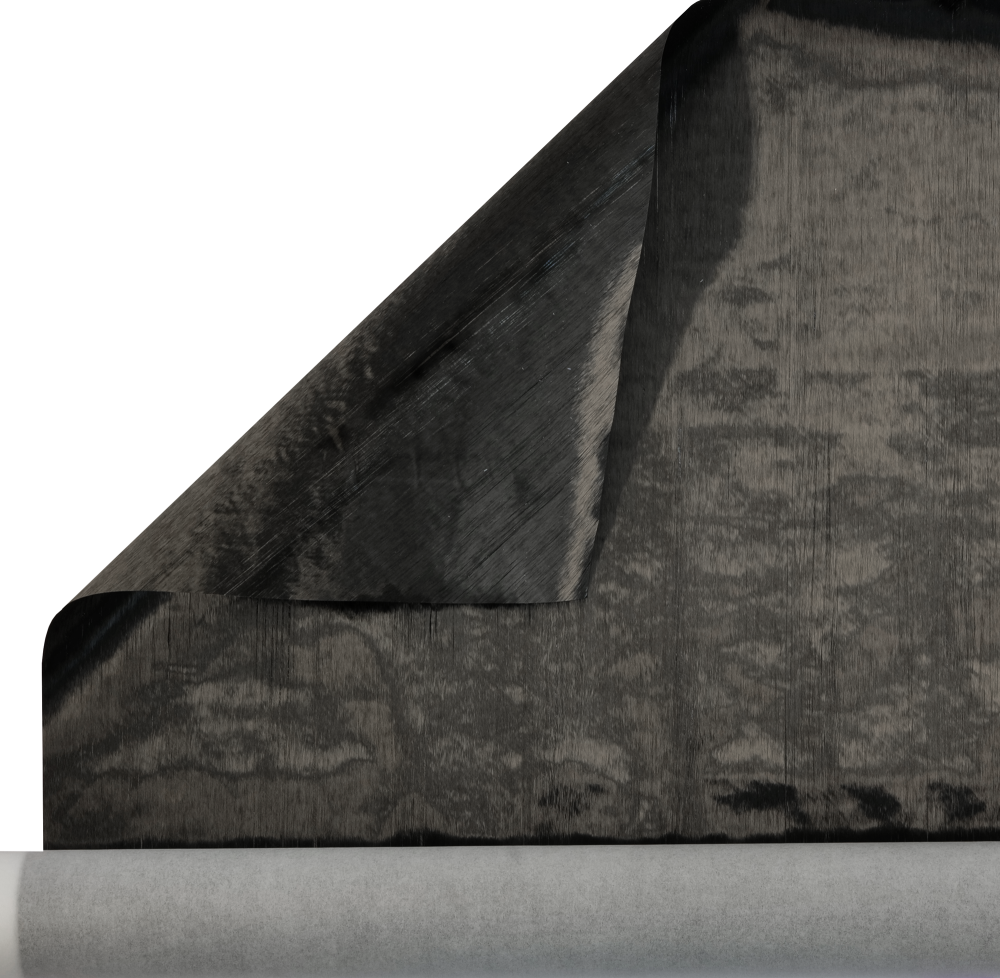

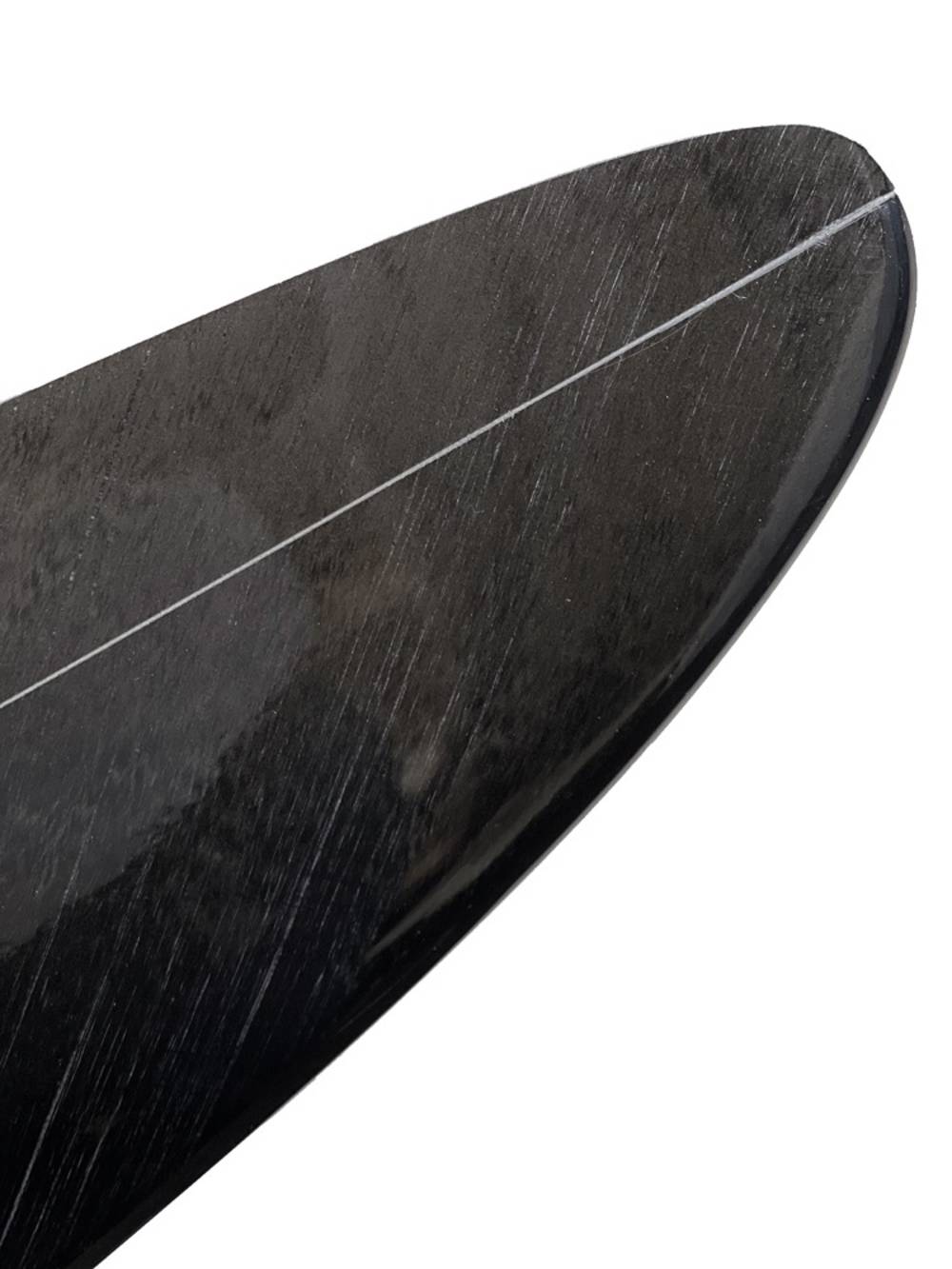

R&G is the official distributor of CARBOWEAVE spread tow fabrics. We are very pleased to now offer our customers the second generation of ultra-lightweight carbon fibre NCFs, which show a difference in quality through their appearance quite clearly. The fibre distribution is much more homogenous, thus the fabric itself does not incorporate clusters of fibres or holes. The fibre orientation –this is the even more important criterion– is absolutely straight and virtually free of undulation. Furthermore, improved surface quality is achieved in comparison to its preceding material.