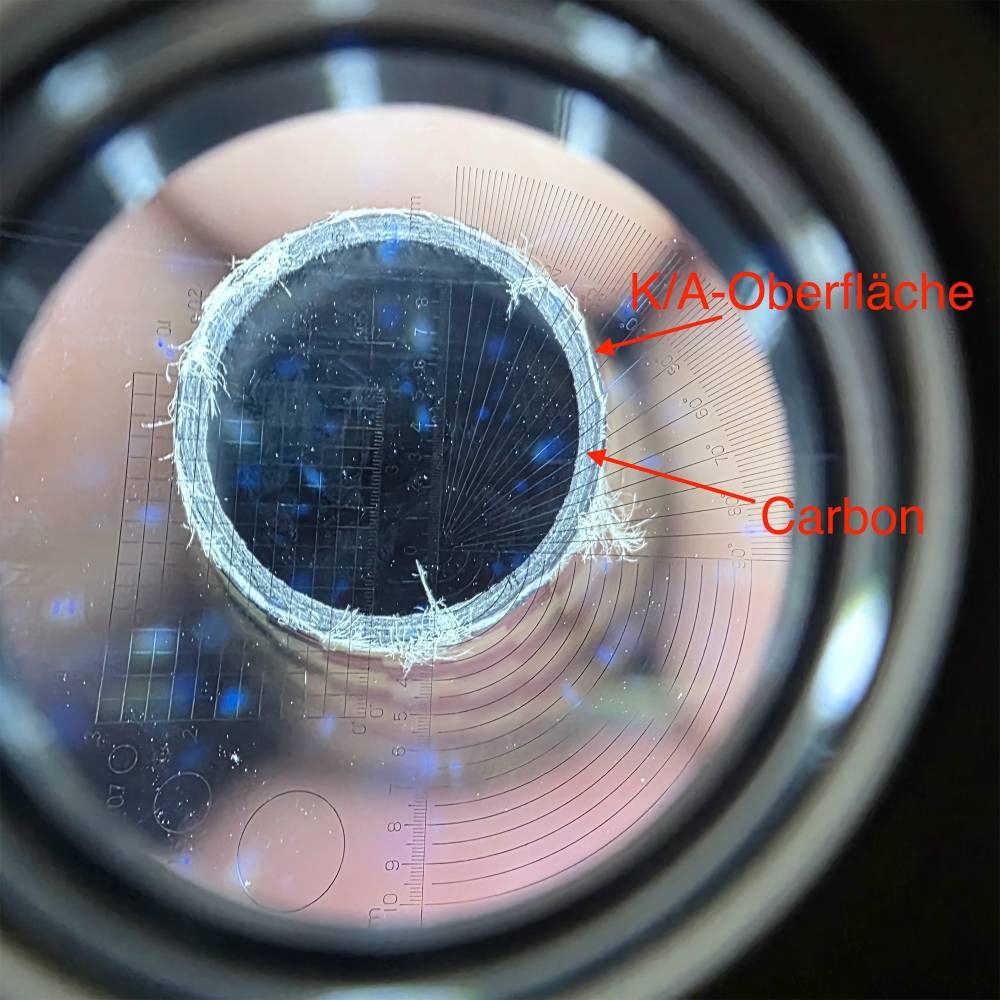

C/A-Carbon round tube, 3k-PW

Wound round tubes with a smooth surface finish of 3k carbon/aramid hybrid fabric in plain weave, clear-coated glossy. The underlying core layer consists of UD fabric. High-quality epoxy resin matrix.

Characteristics:

Lightweight, excellent corrosion and heat resistance and electrical conductivity. Very good flexural and hoop stiffness.

After laminating, the wound CFK round tubes are ground (round) to size and then coated.

Tolerances:

Deviation in diameter ± 0.1 mm. Deviation in straightness max. 1 mm/m.

These tubes are usually not telescopic or cannot be telescoped without post-processing. Telescopic, cylindrical tubes see here.

Application:

E. g. Pompfen construction for the sport "jugger"

Processing:

Fraying of aramid laminates during sawing is a known issue. The cause lies in the high toughness of the fibre and the low melting temperature of the resin compared to the fiber.

Here are the technically proven measures to effectively minimize fraying:

1. Choice of the right tool

Saw blade type

:

- Fine-tooth, diamond- or CBN-coated saw blades are ideal.

- Negative rake angle (–5° to 0°) reduces fibre tearing.

- Segmented (diamond) discs with a continuous edge usually provide the cleanest edge.

2. Speed and feed

- High cutting speed but low feed reduces fiber deformation.

- Avoid overheating (the resin can soften, causing fibers to be torn out).

- Speed: for a 100 mm saw blade about 12,000–18,000 rpm, feed: about 30–60 mm/min, depending on tool geometry and material (the reference values depend on the tool used; we recommend own pre-tests for optimum results)

3. Pretreatment (optional)

- Tape (well-adhering cloth tape) applied on both sides along the cut line – reduces splittng

4. Post-processing

- Light sanding with fine sandpaper

- Seal edges if necessary (epoxy resin, cyanoacrylate glue) to prevent delamination.