CARBOWEAVE® IMS Carbon NCF 40 g/m² (biaxial), 60 x 310 cm

The CARBOWEAVE® IMS carbon fibre biaxial non-crimp fabric 40 g/m² is an ultra-lightweight spread tow carbon non-crimp fabric for demanding lightweight constructions. It is made from Tenax® IMS65 intermediate modulus carbon fibres and offers very high stiffness, tensile strength and excellent drapability – ideal for components where low weight and performance are the main focus.

Overview – Product properties

Material/fibre: Made from Tenax® IMS65 (Intermediate Modulus) carbon fibre

Fibre fineness: 24k / 830 tex

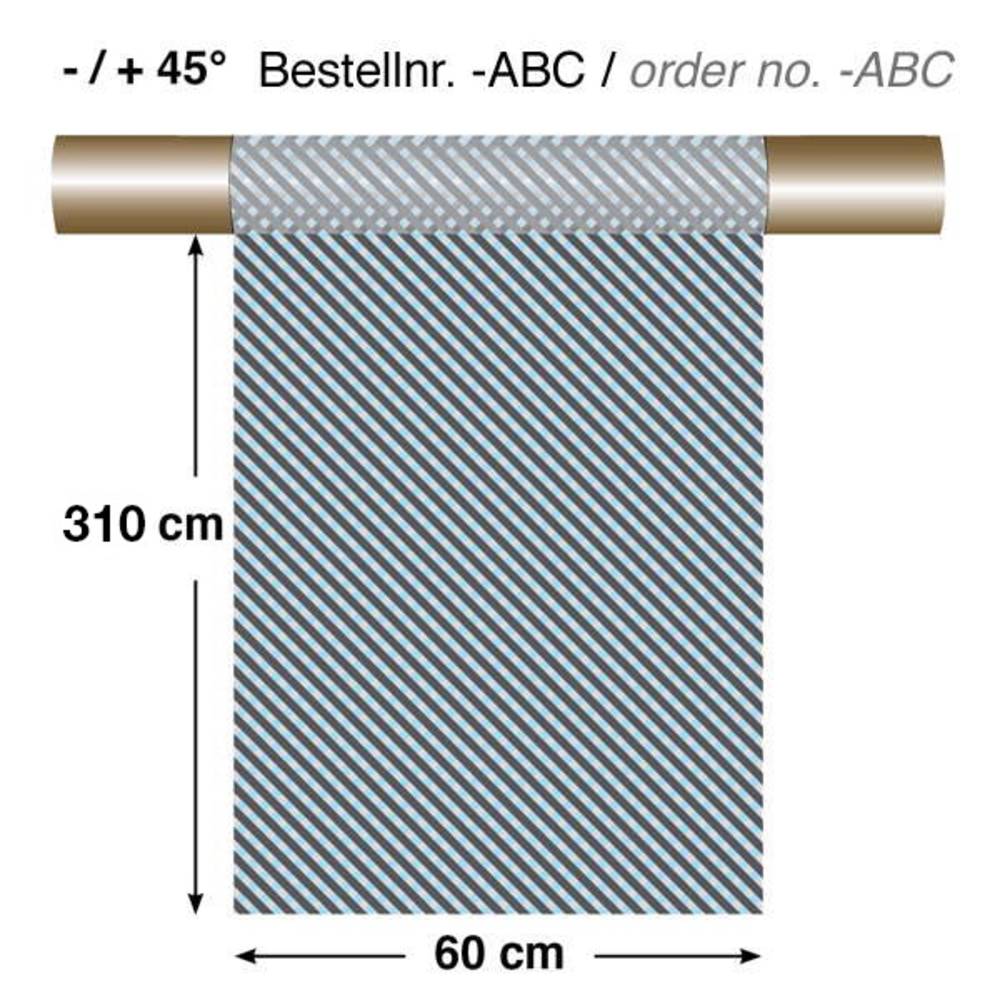

Areal weight: 40 g/m² (20 g/m² + 20 g/m²)

Fabric construction: Biaxial (2 × UD layers)

Fibre orientation: +/- 45° or mirrored −/+45°

Binder: Epoxy-compatible

Dimensions: 60 cm × 310 cm

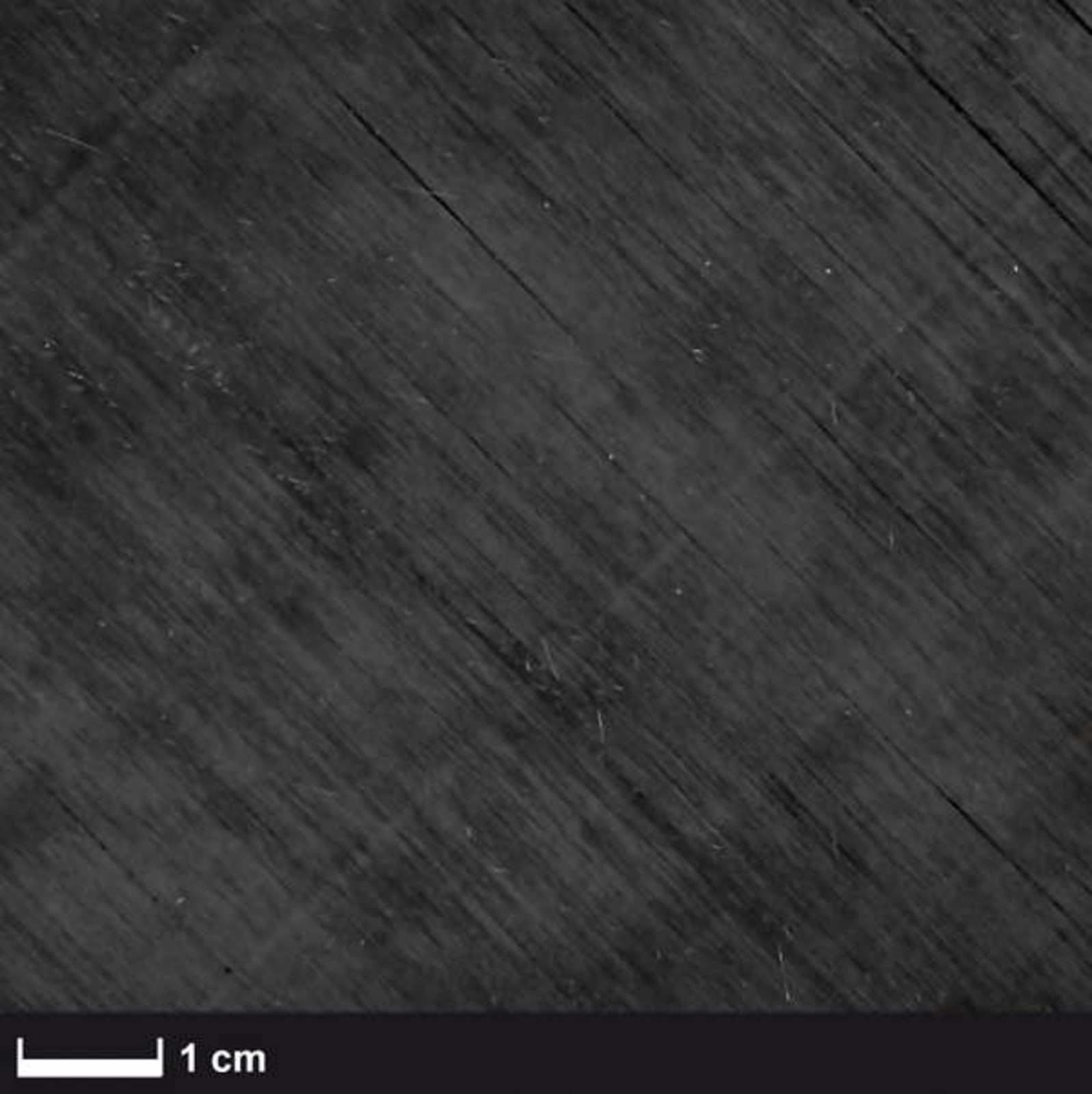

Characteristics: Very homogeneous fibre distribution, virtually free of waviness, smooth surface

Applications: Motorsport, boat building, sports equipment, model making

Product details & application

IM carbon fibre (Intermediate Modulus)

IM carbon fibres are suitable for very lightweight applications. Compared to standard carbon fibres (e.g. HT types), this fibre type provides approx. 20% higher stiffness and approx. 25% higher tensile strength with virtually identical elongation at break.

Biaxial non-crimp fabric ±45° – ideal for torsion & shear

The biaxial non-crimp fabric consists of two unidirectional layers at an angle of ±45°, fixed with an epoxy-compatible binder.

Advantage: torsion layers can be laminated efficiently without waste.

Processing note (warping in very thin components)

With very thin components (e.g. trailing edges of wings or tailplanes in model aircraft), warping may occur if mirrored laminates are not used. Therefore, this quality is available in both +/-45° and −/+45°.

Calculated data for hand lay-ups with 35 vol.% fibres:

Resin consumption: 48 g/m², laminate thickness: 0.060 mm, laminate weight: 88 g/m²

Comparison of Tenax® fibres

| |

IMS65 |

UMS40 |

HTS40 |

| Tensile strength, MPa |

6000 |

4700 |

4400 |

| Tensile modulus, GPa |

290 |

390 |

240 |

| Elongation at break, % |

1.9 |

1.2 |

1.8 |

R&G is the official distribution partner for CARBOWEAVE spread tow non-crimp fabrics. With the 2nd generation of ultra-lightweight carbon fibre non-crimp fabrics, a quality is available that already shows a clear visual difference: the fibre distribution of the individual layers is significantly more homogeneous – meaning there are no nests or holes in the fabric. The fibre orientation is very straight and virtually free of waviness; in addition, an improved surface quality is achieved compared to previous materials.

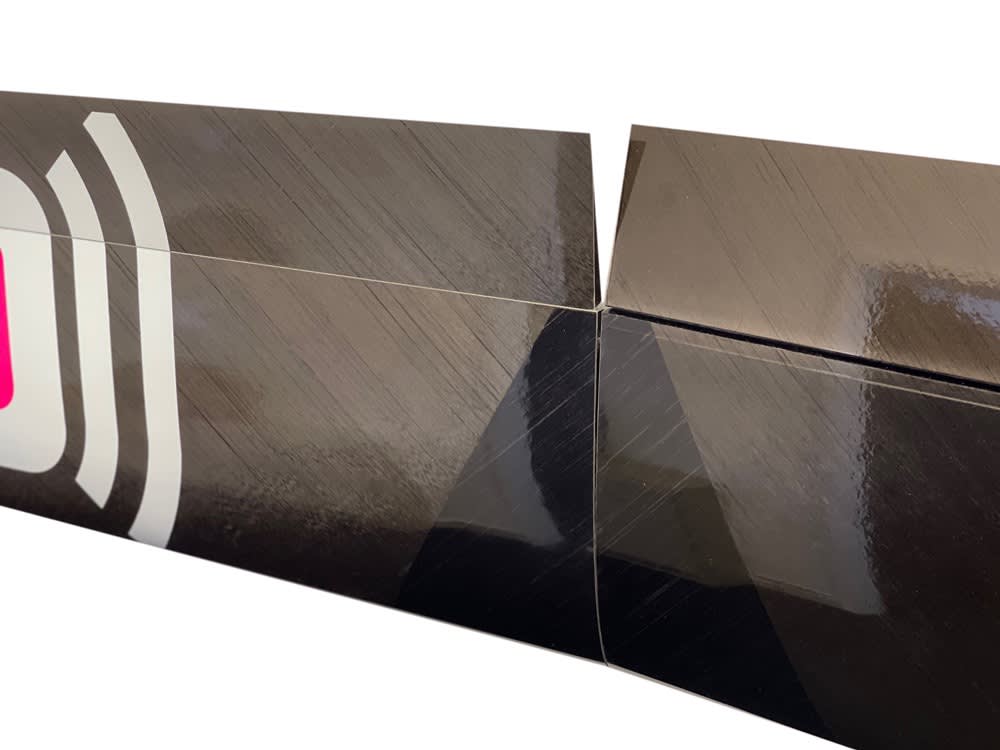

F3X tailplane made from Carboweave®/Rohacell