Carbon fibre sleeve Ø 60 mm / 45° / 3k

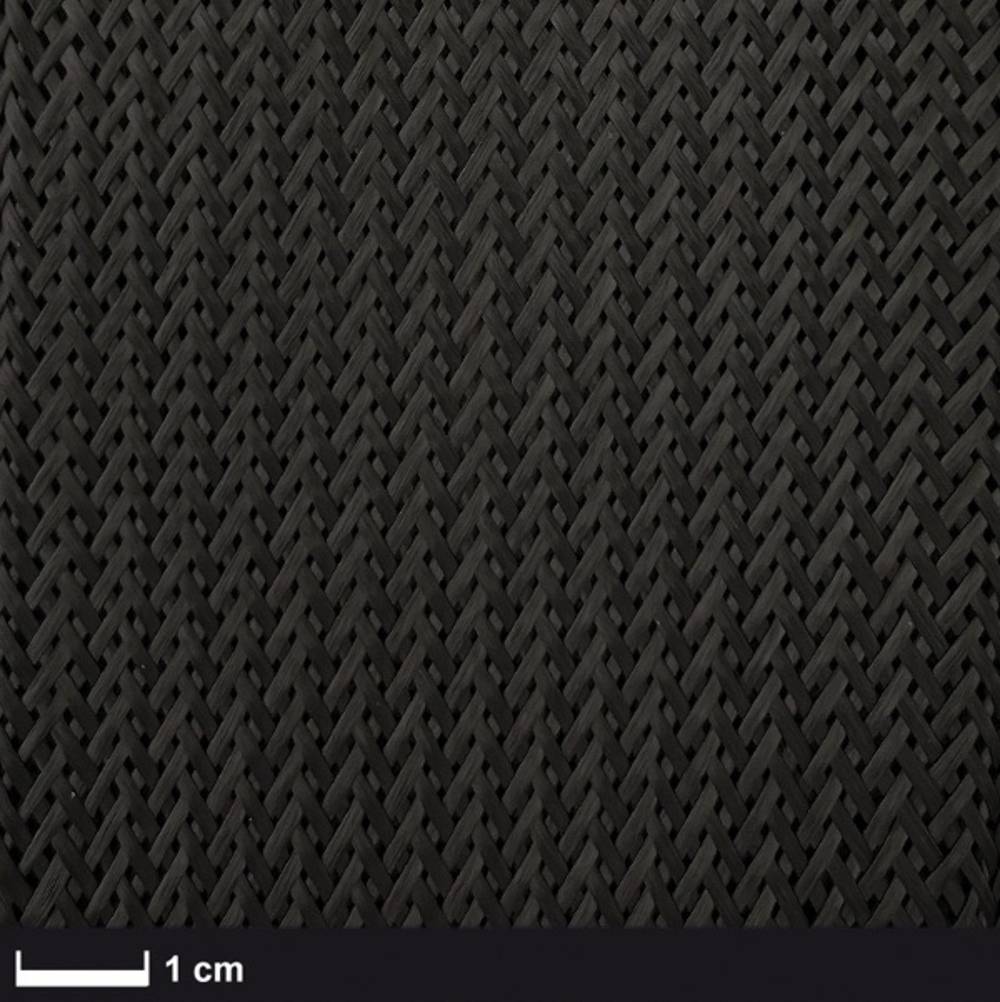

Fibre: Torayca® T300J 200 tex (3k)

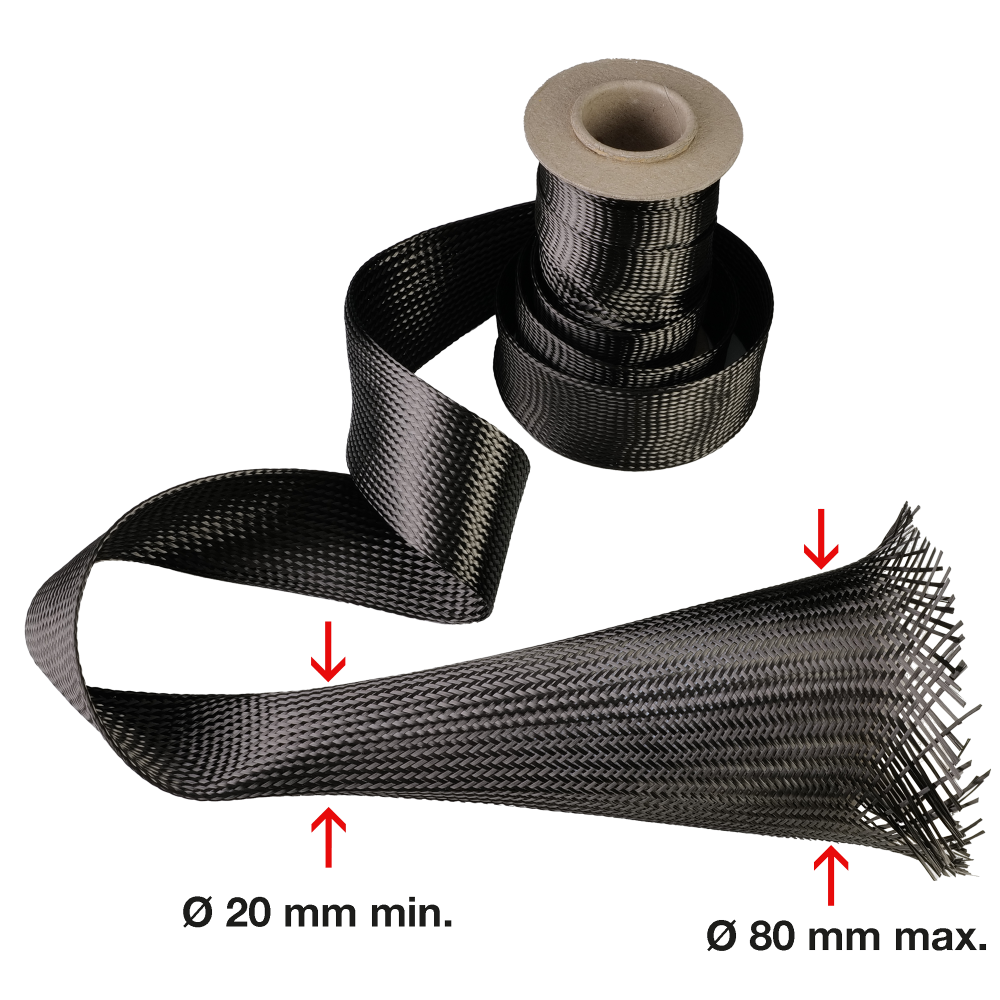

Diameter: approx. from 20 - 80 mm (depending on fibre angle)

Ends: 144

Width (stretched): 26 ± 1 mm

Weight (stretched): 29,49 ± 1 g/m

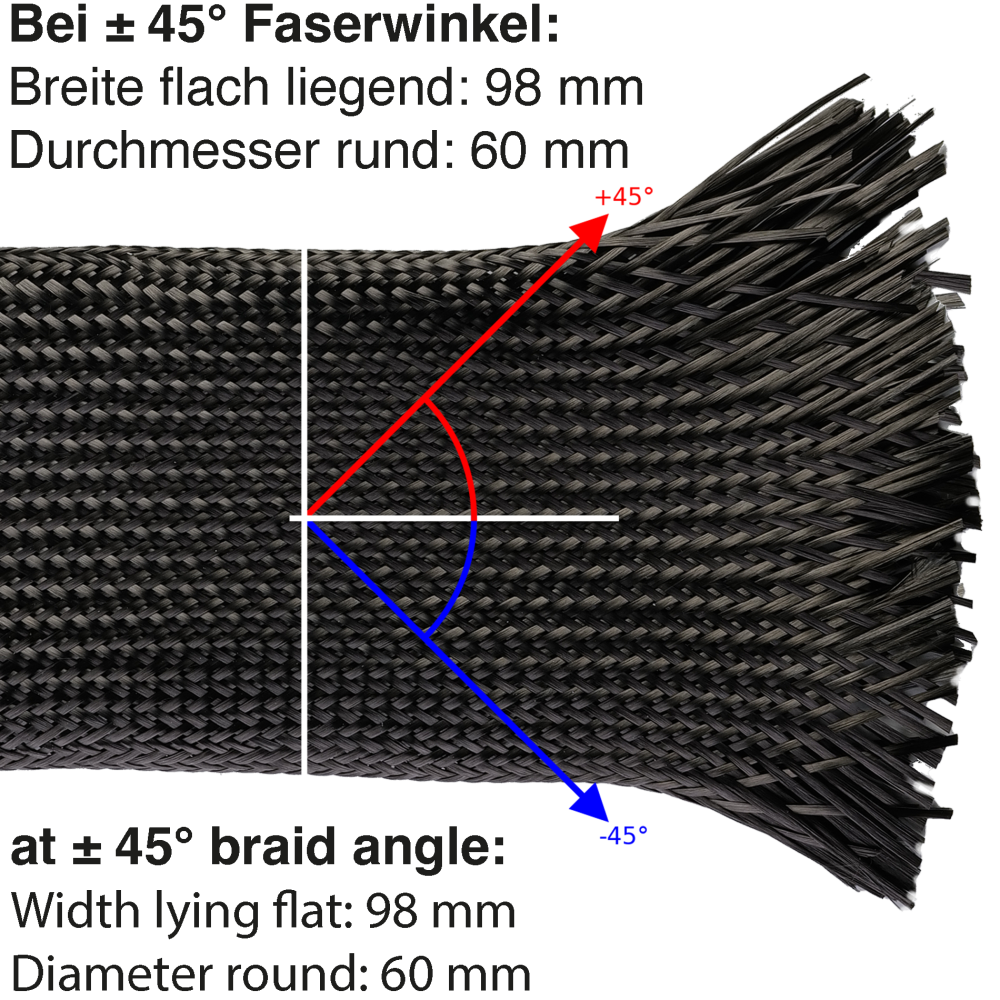

Technical data at 45° braid angle:

Diameter: 60 mm

Width: 98.0 mm

Application:

Torsion-proof pipes of various diameters. Orthopaedic engineering (prosthesis), sports equipment construction. The sleeve diameter can be varied by clenching or stretching. Delivered in a stretched condition.

Processing:

Use plenty of R&G release spray on the core material (slide coating) and allow it to dry. Pass the sleeve over the material and pull both ends for proper fit – fit under tension if necessary. Apply resin with a brush. The area to be processed can be warmed using a hairdryer if required. This will liquify the resin and impregnate the fibre quickly and safely. (Do not forget resin fumes – ensure that the room is well aired or wear a protective mask.) The core is gripped following hardening and the pipe is removed. Small-size components may be pre-frozen. In this way, it is easier to remove the shrunken metal core.

Please note:

For technical reasons, it is not possible to wind up sleeves at a fibre angle of 45°. The amounts differ therefore on the length at 45°.