Compoflex® SB RF3, width 152 cm

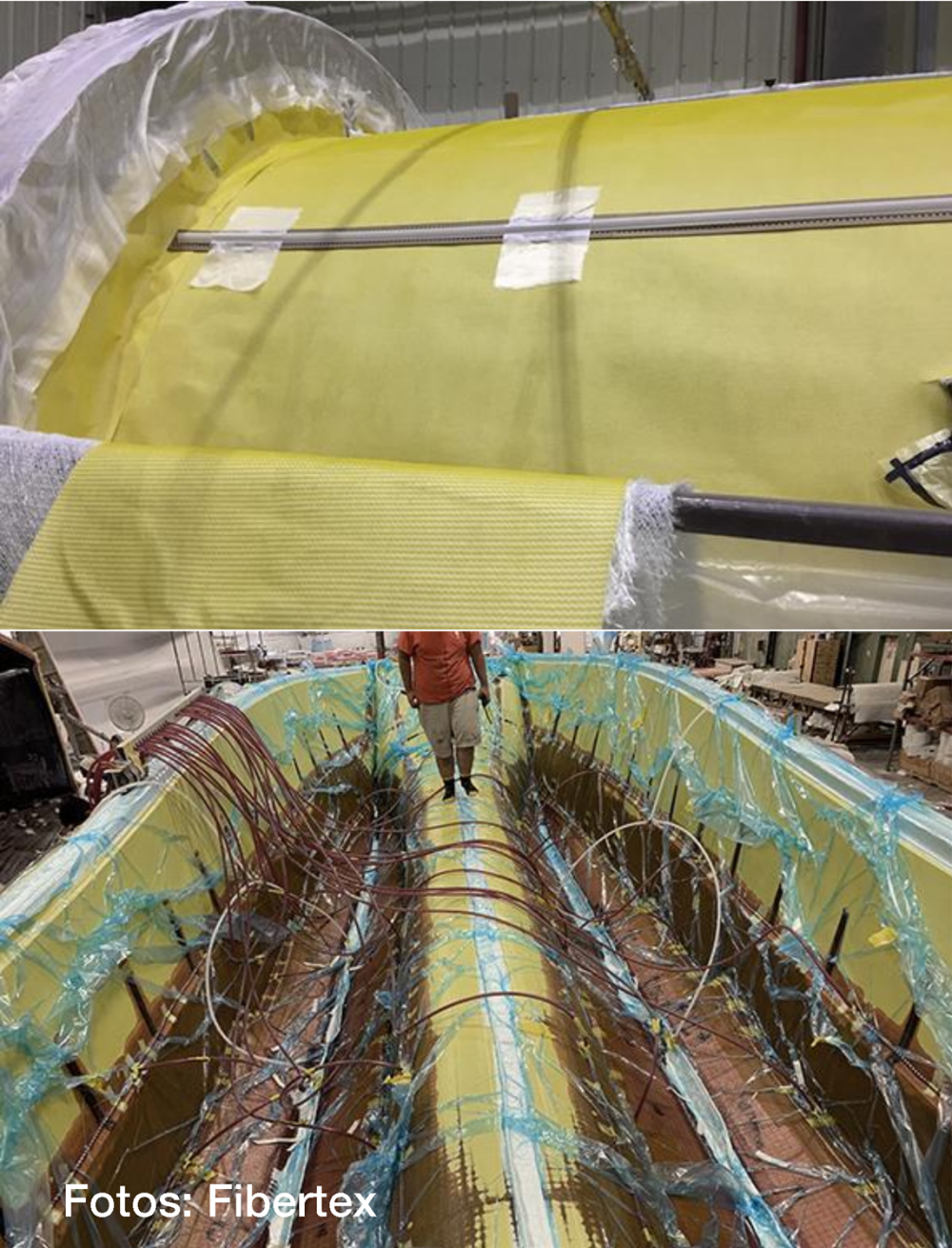

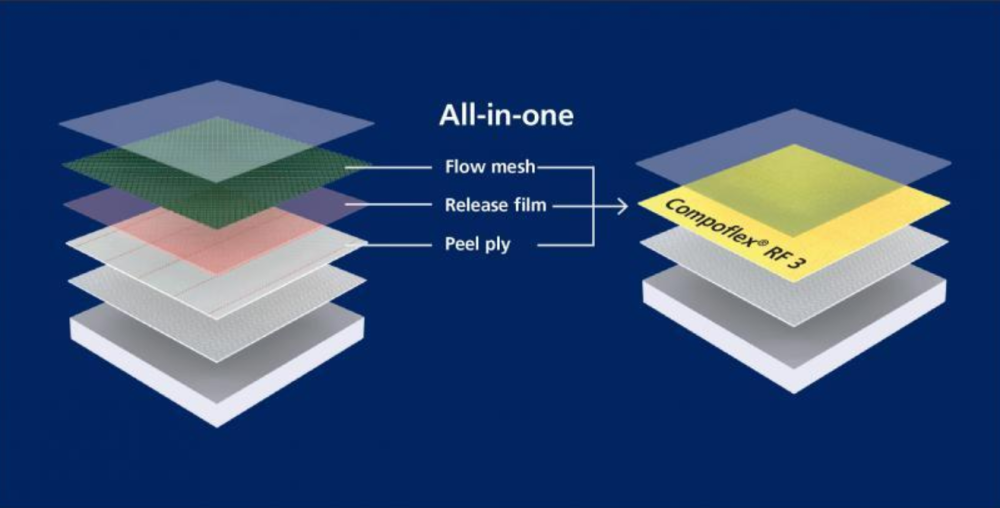

Compoflex® Products1 from Fibertex replace up to three consumables - peel ply/release fabric, release film and breather/flow aid - with a single product in the manufacture of composite components.

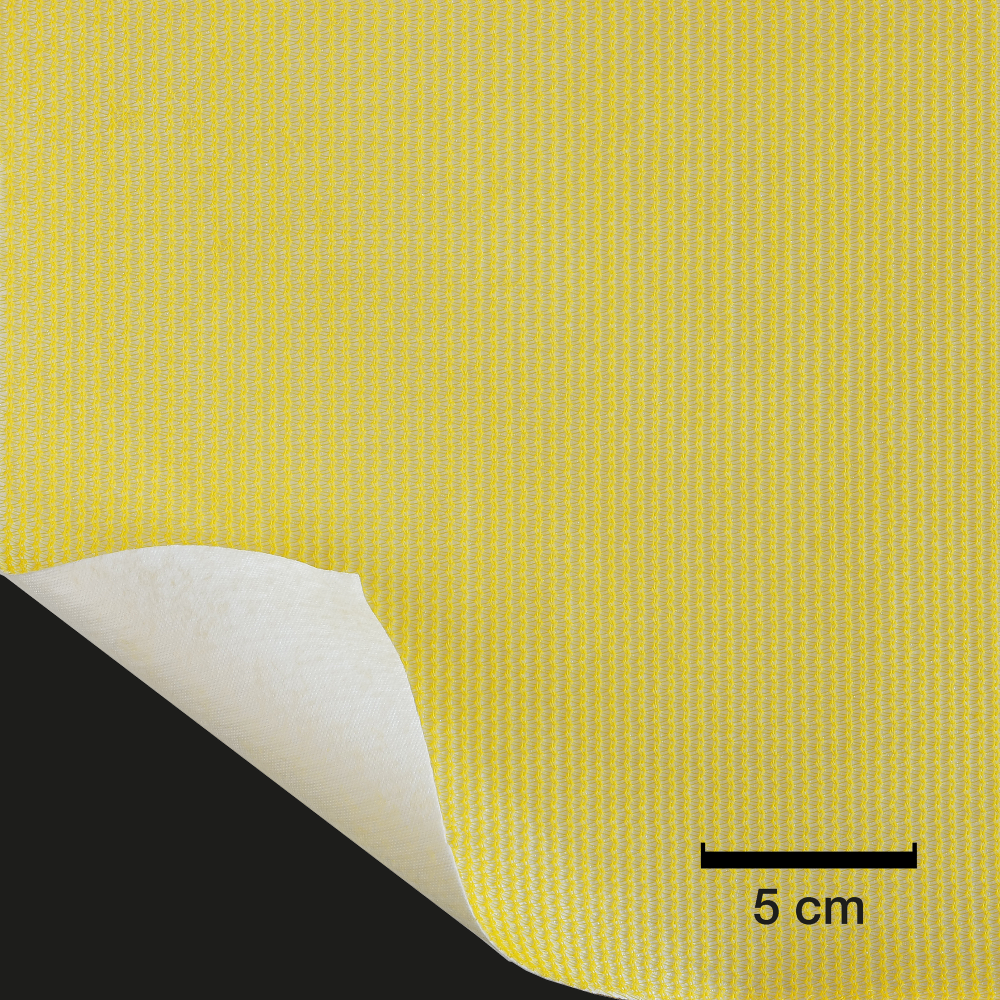

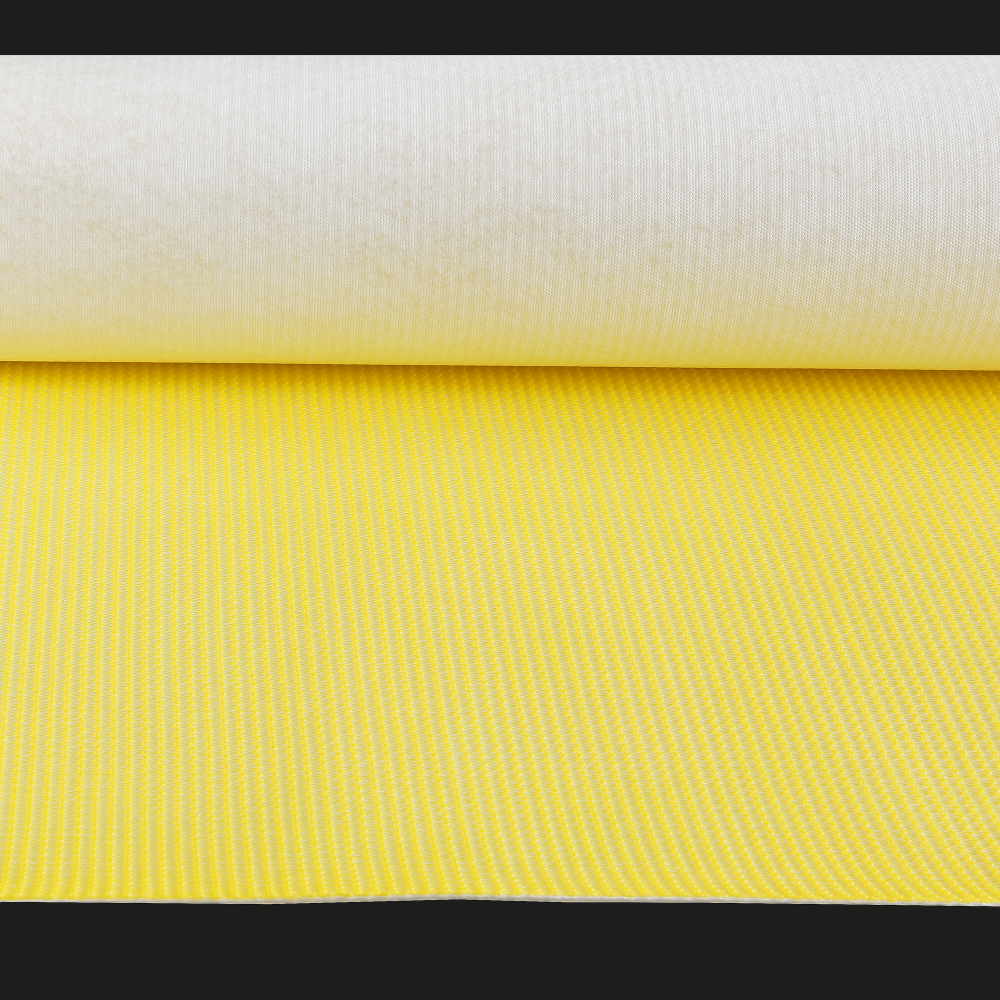

Compoflex® SB RF3 is a peel ply with release film and flow aid

- Rough surface, suited for secondary bonding

- Well suited for polyester, vinyl ester, epoxy, phenolic and other resin types

- Suitable for the infusion process

Technical data Compoflex® SB RF3:

Recommended operating temperature: 145 °C 2

Fibre type: Polypropylene (PP), High-density polyethylene (HDPE) grid

Colour: White/yellow

Weight (ISO 9864): 335 g/m²

Thikness (ISO 9863 - 1): 1.6 mm

Tear strength MD/CD (ISO 9073 - 4): 280 N/188 N

Pore size (ISO 12956): < 10 μm

Width: 152 cm

Compoflex® offers direct advantages in the manufacturing process:

- Superior peeling properties

The micro-porous surface and the low surface tension of polypropylene (PP) nonwovens ensure that Compoflex® peels at one fifth of the force needed to peel conventional peel ply. - Uniform bleeding

The micro-porous perforation enables uniform bleeding, ensuring stronger and lighter laminates. Overlapping is possible, without compromising laminate quality. - Time and cost savings

Fewer consumables, combined with easy peeling, reduce costs and handling time, simplifying the process. - "Easy release" minimises resin dust

Compoflex® peels easily. Most of the cured resin remains in the Compoflex®. This significantly reduces air pollution compared to conventional materials. Compoflex® therefore contributes to healthier working conditions.

Further information:

1 Compoflex®-Products (available at R&G):

| Material | Weight | Colour | Process | Function |

for |

|

| Compoflex® 150 | PP | 150 g/m² | white | Infusion | Release film + release film | no |

| Compoflex® SB 150 | PP | 150 g/m² | white | Infusion | Peel ply + release film | yes |

| Compoflex® 250 | PP | 250 g/m² | white | Moulding | Release film + release film + 150 g breather | no |

| Compoflex® SB 250 | PP | 250 g/m² | white | Moulding | Peel ply + release film + 150 g breather | yes |

| Compoflex® SB RF 3 | PP/HDPE | 335 g/m² | weiß/yellow | Infusion | Peel ply + release film + flow aid | yes |

2 Operating temperature:

The recommended maximum processing temperature is 144 °C (293 °F). The melting point for polypropylene is 165 °C (329 °F). However, it is possible to use Compoflex® at 200 °C (392 °F), as Compoflex® still works reliably before the melting point is exceeded. After cooling, the material becomes stable again and peeling is as easy as ever. We recommend carrying out a test on a small part first.

3 MD = Machine direction

CD = Cross direction

Compoflex® SB RF 3 (152 cm) roll/ 1 m

(surface area = 1.52 m²)

Item no. FD-124241-1 Only 6 left in stock, more on the way (delivery time 1-2 days)

Add to Shopping ListScaled Price

- From Qty 2: 5,00%

Compoflex® SB RF 3 (152 cm) roll/ 2 m

(surface area = 3,04 m²)

Item no. FD-124241-2 Only 3 left in stock, more on the way (delivery time 1-2 days)

Add to Shopping ListScaled Price

- From Qty 2: 5,00%

Compoflex® SB RF 3 (152 cm) roll/ 3 m

(surface area = 4.56 m²)

Item no. FD-124241-3 Only 5 left in stock, more on the way (delivery time 1-2 days)

Add to Shopping ListScaled Price

- From Qty 2: 5,00%

Compoflex® SB RF 3 (152 cm) roll/ 5 m

(surface area = 7.6 m²)

Item no. FD-124241-4 Only 5 left in stock, more on the way (delivery time 1-2 days)

Add to Shopping ListScaled Price

- From Qty 2: 5,00%

Compoflex® SB RF 3 (152 cm) roll/ 10 m

(surface area = 15.2 m²)

Item no. FD-124241-5 Only 4 left in stock, more on the way (delivery time 1-2 days)

Add to Shopping ListScaled Price

- From Qty 2: 5,00%

Compoflex® SB RF 3 (152 cm) roll/ 20 m

(surface area = 30.4 m²)

Item no. FD-124241-6 Only 1 left in stock, more on the way (delivery time 1-2 days)

Add to Shopping ListScaled Price

- From Qty 2: 5,00%

Compoflex® SB RF 3 (152 cm) roll/ 61 m

(surface area = 92.72 m²)

Item no. FD-124241-9 Only 2 left in stock, more on the way (delivery time 1-2 days)

Add to Shopping ListScaled Price

- From Qty 2: 5,00%

- From Qty 3: 10,00%

- From Qty 4: 15,00%

- From Qty 8: 20,00%

all Prices price incl. VAT, possibly plus shipping