Build a Drone

Build a Drone - Materials and Guide for DIY Drone Building

Why Fiber Composites for Drone Building?

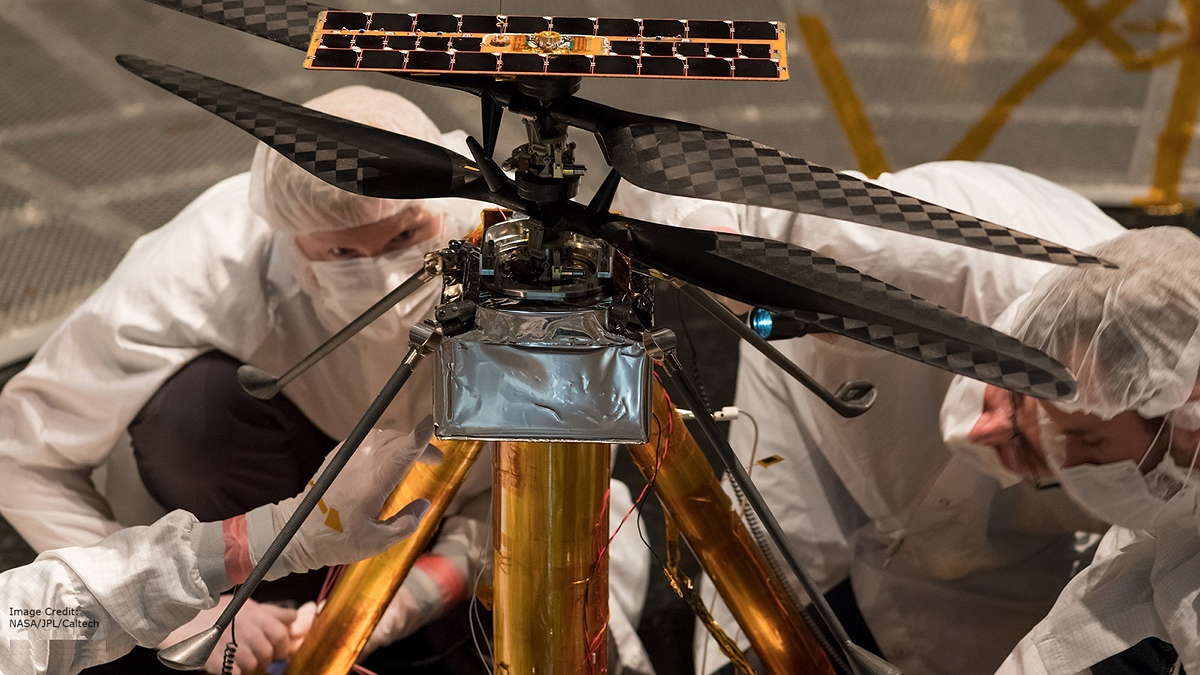

Building a drone places high demands on the materials used. Low weight, high strength, and vibration damping are crucial for optimal flight performance and stability. Fiber-reinforced composites such as carbon fiber (CFRP), glass fiber (GFRP), and aramid offer these properties in ideal combination.

Carbon fiber materials enable weight reduction of up to 50% compared to aluminum while providing higher stiffness. Excellent vibration damping significantly improves image quality for camera drones. Glass fiber reinforced plastics offer a cost-effective alternative for less critical components.

© OXEON AB

© OXEON AB

Build a Drone - First Steps for Beginners

Getting started with drone building begins with planning and material selection. First, define the intended use: racing, camera work, or recreational flying determines the requirements. A simple quadcopter frame is ideal for initial projects.

Basic equipment includes carbon fiber plates for the central frame, carbon fiber tubes for the arms, and epoxy adhesives for connections. Beginners should start with pre-fabricated carbon fiber semi-finished products before using complex lamination processes. A simple tool set with saw, files, and sandpaper is sufficient for first build projects.

How to Build a Drone - Step by Step with the Right Materials

Manufacturing a high-quality drone requires appropriate materials and tools. Systematic construction proceeds from the frame through the arms to surface treatment. A typical build uses load-bearing structural elements made from fiber composites and precise connections using epoxy resins.

Frame Construction and Structure

The basic structure of a drone consists of a central base plate and components mounted on it. Carbon fiber plates in thicknesses of 1-6 mm form the basis for stable and lightweight frames. The plates are precisely cut and joined using epoxy adhesives or laminating resins.

For complex geometries, lamination with carbon fiber fabrics is suitable. Multiple layers of carbon fiber fabric are saturated with epoxy resin and cured under vacuum. This enables the production of seamless, high-strength structures.

Drone Arms and Landing Gear

Drone arms transfer motor loads to the central frame and must withstand high stresses. Carbon fiber tubes with outer diameters of 8-25 mm provide optimal stiffness with low weight. Pultruded tubes ensure uniform wall thicknesses and precise tolerances.

Landing gear is manufactured from carbon fiber rods or tubes. Connection is achieved through specially manufactured node points from carbon fiber plates or by lamination with aramid fabric for increased impact resistance.

Surface Treatment and Connections

All connections are made with structural epoxy adhesives or laminating resins. Mixing ratios must be precisely maintained for optimal strength values. Surface treatments with gel coats or clear lacquers protect the fiber composites from UV radiation and environmental influences.

© OXEON AB

© OXEON AB

Carbon Drone Frame - Lightweight Design for Maximum Flight Time

Carbon fiber drone frames offer the best weight-to-strength ratio. The high specific stiffness enables precise flight maneuvers and reduces vibrations. Low-shrinkage epoxy resins ensure dimensionally stable components without warpage.

Carbon Fiber Plates for Drone Frames

Carbon fiber plates in UD layup 0°/90° provide optimal stiffness in both main directions. Common thicknesses range from 1.5 mm for small racing drones to 6 mm for heavy camera drones. The plates can be precisely machined with diamond cutting discs or waterjet cutting.

For particularly lightweight constructions, sandwich plates with aramid honeycomb core are suitable. These achieve high bending stiffness with minimal weight.

Carbon Profiles and Reinforcements

Reinforcements and connecting elements are manufactured from carbon fiber profiles. L-profiles, U-profiles, and rectangular tubes enable precise mechanical connections. The profiles are cut to exact lengths by CNC machining.

Materials for Different Drone Types

Different drone types place varying demands on materials. Racing drones require maximum weight savings, while industrial UAVs are designed for durability and load capacity.

Racing Drones - Ultra-Light and Robust

Racing drones require minimal weight with maximum crash resistance. Carbon fiber plates in 1.5-3 mm thickness form compact, stiff frames. High-strength carbon fibers (HT fibers) offer optimal crash properties. All connections are made with low-viscosity epoxy resins for minimal adhesive layer thickness.

Camera Drones - Vibration-Free and Stable

Camera drones require optimal vibration damping for shake-free recordings. Aramid fabric inserts between carbon fiber layers reduce vibration transmission. Sandwich constructions with PVC rigid foam core provide high stiffness without weight penalty.

Industrial UAVs - Durable and Heavy-Duty

Industrial UAVs must withstand high continuous loads. Thick-walled carbon fiber tubes and reinforced node points ensure long service life. UV-resistant gel coats protect against weather influences. Aramid reinforcements in critical areas increase impact toughness.

Tools and Accessories for Drone Building

Precise tools are essential for high-quality drone components. Diamond cutting discs enable clean cuts in carbon fiber materials without chipping. Laminating tools such as debubbling rollers and pressure rollers ensure bubble-free lamination.

Digital precision scales ensure exact resin mixtures. Vacuum pumps and vacuum films enable professional lamination processes for optimal component properties. Release agents prevent adhesion to tools and molds.

Tips for Your First Drone Build

Precision is crucial for airworthy drones. All arms must have exactly equal lengths and be mounted symmetrically. Use scribing needles and steel rulers for precise markings on carbon fiber plates.

Epoxy adhesives should cure at room temperature for at least 24 hours. Clamps or weights ensure uniform pressure during curing. Excess adhesive must be removed before curing, as cured epoxy resins are difficult to machine.

Test the alignment of all components before final bonding. A mounting template made from MDF boards helps with correct positioning of drone arms. Center of gravity and balance must be checked before first flight.

© Philip Braun

© Philip Braun

Frequently Asked Questions about Drone Building (FAQ)

What carbon plate thickness for racing drones?

2-3 mm carbon fiber plates offer optimal weight-to-strength ratio for racing applications.

Can glass fiber materials be used?

GFRP is suitable for less critical areas such as covers or landing gear. Load-bearing structures should be made from carbon fiber.

How long do epoxy connections last?

Properly executed epoxy bonds achieve the service life of the base materials. UV protection extends durability.

Are sandwich constructions necessary?

Sandwich plates with aramid honeycomb core offer increased stiffness for larger camera drones. Small racing drones usually require solid material.

What surface treatment is required?

Carbon fiber surfaces are ready for use without further treatment. Clear coat or gel coat provide additional UV protection and facilitate cleaning.

Troubleshooting - When Things Go Wrong

Cracks in carbon components

Small cracks can be repaired by over-laminating with carbon fiber fabric. The damaged area must be sanded and saturated with epoxy resin.

Adhesive bonds failing

Insufficient surface preparation is the most common cause. Carbon fiber surfaces must be sanded and degreased before bonding.

Flight imbalance

Asymmetric mounting or different arm weights cause imbalance. Precise length measurement and weight balancing with additional masses solve the problem.

Vibrations in camera recordings

Rigid connections transmit motor vibrations directly. Aramid interlayers or vibration dampers reduce transmission.

Poor surface quality

Bubbles in the laminate result from insufficient venting. Vacuum technology or careful rolling eliminates air inclusions.